In the dynamic realm of construction, knowledge and compliance with special inspections are non-negotiables. For contractors bound by the law to undertake special inspections, finding the right allies is critical for getting projects over the line.

In this article, we aim to provide you with a comprehensive understanding of special inspections, their importance, and how partnering with professionals like Level Engineering can be your secret to success, all while ensuring safety and efficiency goes uncompromised.

Structures are getting more complex by the day, Special inspectors use their critical expertise to perform inspections on structures according to the International Building Code (IBC). They check if the code and approved construction documents are being followed. It’s important to have an expert on your side to ensure you stay within the lines as projects develop.

What types of special inspections does your project need?

All engineered building projects need special inspections. Here are the types of inspections required for your project:

Concrete inspections

Concrete inspection is one of the inspections required to check the concrete used in structures to ensure it meets IBC standards. They check how it’s mixed, placed, and cured. The adopted ACI design codes, such as ACI 318, have rules for designing, testing and inspecting concrete structures at job site. Special inspections involve concrete tests such as slump, tensile strength, and compression.

In addition, special inspections verify the concrete mix, placement, and curing methods used on your structure.

If you don’t follow the ACI codes, the concrete material will be poor. This caused the collapse of the Champlain Towers South in 2021. The parking garage’s concrete columns, beams, and walls cracked and crumbled. The building was 13 stories tall.

Figure 1: Cracks on a Desultory Concrete Column

Steel inspections

Inspect all steelwork in your project to meet adopted AISC and AISI standards. AISC 360 outlines special inspections required for steel dimensions, fabrication and sustainable production technology for safety.

The steel used on your buildings requires special inspections to meet the IBC standards. The inspectors must test steel samples using Charpy V-notch, tensile, and hardness checks. As the project owner, ensure special inspectors are present to check the strength, ductility, and integrity of the steel.

3. Masonry Inspections

To make sure your building achieves masonry certification on quality and safety, IBC adopts TMS 402 and TMS 602. These standards guarantee high-quality mortar mixture, grout placement procedures and strong, safe structures.

Special inspections verify the durability and strength of masonry in your structure. Enabled by compressive strength, water absorption, and efflorescence checks.

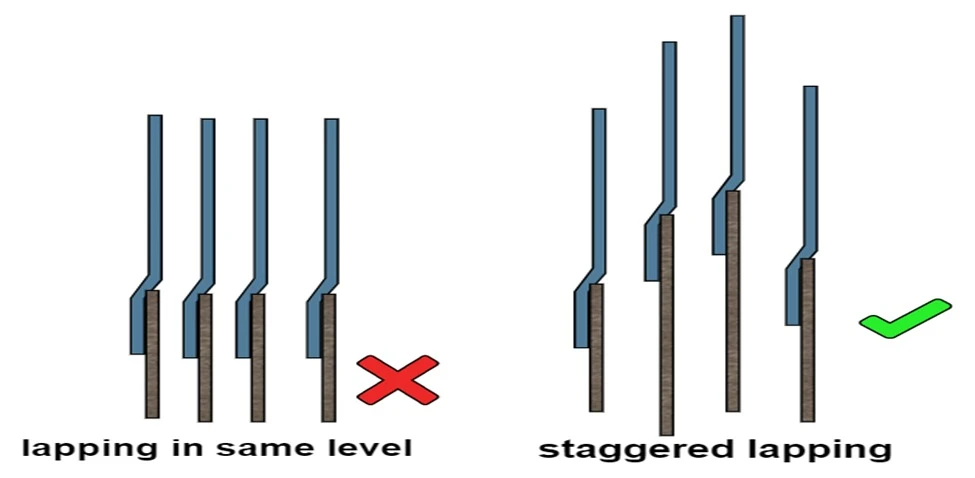

4. Reinforcement inspections

The IBC has specific guidelines for reinforcement weight, diameter, and overlap. For steel reinforcements, IBC suggests a very long overlap gap – at least 40 times the bar diameter. In many cases, failure to adhere to such standards compromises the structure’s strength, safety, and durability. Structural special inspections check if the reinforcements in your project are correct. They make sure they are the right size, connections and in the right position for structural integrity.

5. Bolting Inspections

There is the IBC for New Jersey in 2021. It requires you to follow the rules in sections 2205, 2206, 2207, 2210, and 2211 to meet the bolting standards. Section 1705.2 helps with inspecting high-strength bolt connections on your structure. During installation of steel roof trusses, foundation walls, and columns, remember to call for special inspection service.

Figure 2: High-Strength Bolts

Figure 3: Structural Steel Bolt Sizes and Dimensions

Nondestructive Inspection

Sometimes, you have used very expensive materials in your ongoing or complete construction. It is foolish to destroy your structure for testing in this situation. Hence, special inspectors apply nondestructive inspection to the structure. Nondestructive inspections do not involve the destruction of your already-built structure. There are technologies and equipment suitable for nondestructive inspection. These techniques include:

- Ultrasonic testing (UT) involves applying high-frequency sound waves to detect defects in materials.

- Magnetic particle testing (MT) uses electromagnetic fields to find defects in ferromagnetic materials.

- Radiographic testing uses gamma rays or X-rays to detect defects in construction materials.

Nondestructive tests (NDT) can find and describe defects in components and structures. They also check compliance and safety of the structure.

What do the regulations say?

The International Building Code (IBC)

The IBC has chapters with standards for certification. These standards ensure the safety of the structures we interact with. The standards guide the compliance process to ensure safe, sustainable, and resilient construction. To ensure compliance, IBC works together with several standard development organizations (SDOs), including:

- American Concrete Institute

- American Institute of Steel Construction

- American Iron and Steel Institute

- American Wood Council

- The Masonry Society

- National Fire Protection Association

10 Benefits of Special Inspections Service for You and Your Structure

- Successful completion ~ You will witness a successful completion of your project.

- Positive Return on Investment ~ special inspection increases revenue. It saves costs while increasing the property value. Hence, you will achieve a positive return on investment.

- Safety ~ The project attains a magnificent safety level that surpasses your expectations.

- High Quality ~ Your priority is a high-quality construction work. Special inspections definitely give your project the quality it deserves.

- Sustainability ~ Your project becomes sustainable with minimal environmental impact.

- Financial Success ~ Your main fear is to encounter cost overruns and unexpected expenses. Well-inspected projects stay within the budget and keep you away from financial failures.

- Timely completion ~ You cannot experience construction delays.

- Long-time Value ~ You have a construction project with lasting value and relevance.

- Reputation and Brand Improvement ~ You remain committed to quality and compliance. At the end, your project enhances your pride, reputation, and brand.

Frequently Asked Questions (FAQ)

- Isn’t this just costing me more money? The answer is no, on the contrary, having a trusted special inspector on board can save you huge sums in the long run and will keep projects running smoothly and on time.

- What does site development mean in construction? Site development is the process of preparing construction sites for structural activities. To prepare for construction, special inspectors do soil tests to grade the soil. We clear the land, build roads, and install utilities.

- What are the 7 stages of construction?

- Planning

- Design

- Preconstruction

- Post-construction

- Commissioning

- Handover

- Who Determines What Special Inspections My Project Need? A Registered Design Professional or Structural Engineer of Record. They must prepare a statement listing all required special inspections for the project. It should go with construction documents, drawings, geotechnical reports, etc.

- Who handles hiring of special inspectors? The project owner or design professional must hire a special inspector or approved agency. The inspector or owner’s agent that does the inspection must not be the same as the contractor. But the contractor can hire a special inspector if they are the project owners

- What happens if special inspectors identify a problem? A special inspector identifies a problem in a building. They tell the people involved and suggest a solution before work starts again.

- What should I expect during the special inspection? Special inspection includes checking the design, structure, and materials of the construction.

- How do I find a qualified special inspector? Call us today to help your project get quality special inspection service.